The Case of the Flaked Nickel Plating: Photo Support

By Craig J. Schroeder, P.E., Senior Engineer, Metallurgy for Element Materials Technology

on 2/15/2016 12:11 PM

Photos courtesy of Element Materials Technology

When the coating on the tubes of a water heating unit started failing prematurely, they needed an expert to solve the case. The nickel plating was flaking off, so we gathered evidence to determine the root cause. The following is part of the evidence that we found:

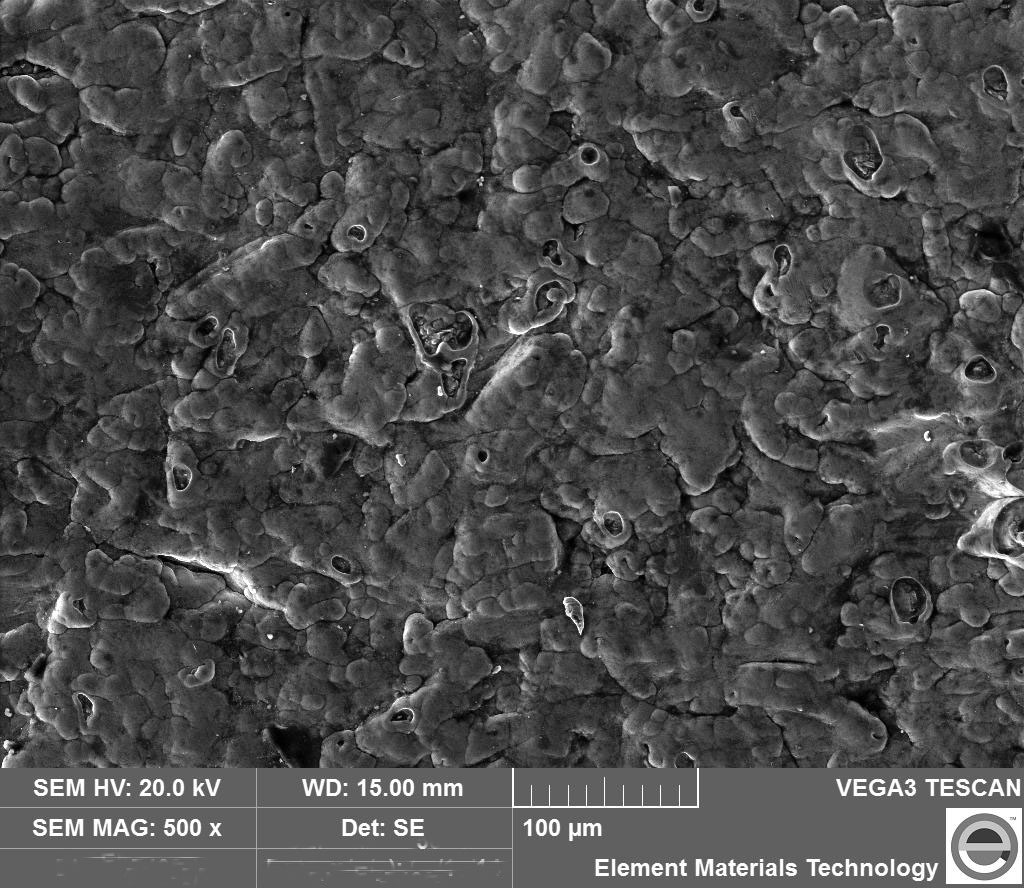

Figure 1. (shown above) This is a scanning electron micrograph of the specimen. It's an inspection via SEM and illustrates the nodular texture of the plating, common for electroless nickel. The texture is presented after rinsing the section with methanol.

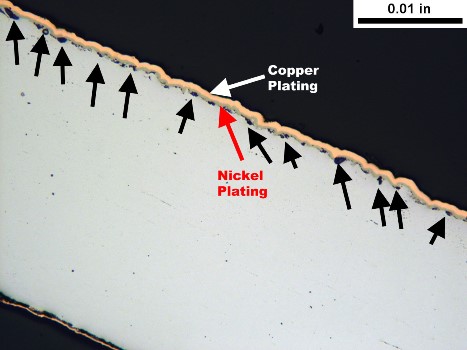

Figure 2.

The cross section of the specimen wall is presented. The red arrow indicates the nickel plating. The white arrow indicates the copper plating. The black arrows indicate the presence of contaminants below the nickel plating. (OM 100X)

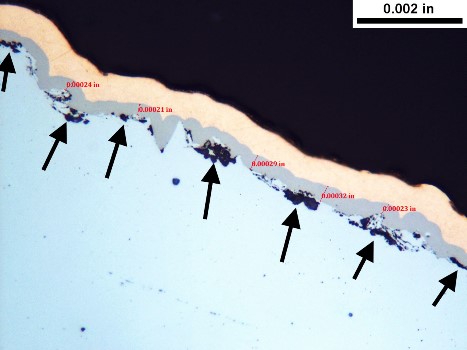

Figure 3.

A higher magnification view of the top center portion of Figure 2 is presented. The red lines indicate the nickel plating thickness measurements. The black arrows indicate the presence of contaminants below the nickel plating. (OM 500X)

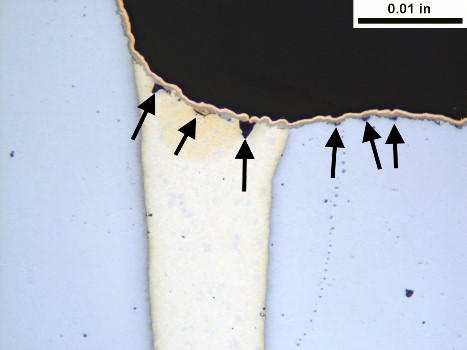

Figure 4.

A

magnified view of a braze joint in the unit is presented. The arrows indicate the presence of

contaminants beneath the nickel plating.

(OM 100X)

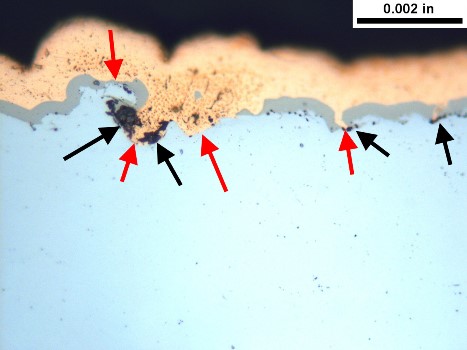

Figure 5.

A

magnified view of the bend radius on the specimen is presented. The black arrows indicate the presence of

contaminants below the nickel plating.

The red arrows indicate the presence of holidays in the nickel

plating. (OM 100X)

Figure 6.

A

higher magnification view of the top center portion of Figure 5 is

presented. The red arrows indicate

the presence of holidays in the nickel plating.

The black arrows indicate the presence of contaminants below the nickel

plating. (OM 500X)

Figure 7.

.jpg)

A scanning electron micrograph of the coatings on the specimen wall is

presented. Dark features are evident

below the coatings.

Figure 8.

A

higher magnification view of the center portion of Figure 7 is presented. The areas selected for EDS analysis are

identified in the view.

To see the original Never Again story in its entirety, check out the March 2016 issue of CoatingsPro Magazine, and find out how the Case of the Flaked Nickel Plating ended!