NACE International/Society for Protective Coatings (SSPC) Joint Surface Preparation Standards — classified as wet abrasive blast (WAB) cleaning and waterjet (WJ) cleaning surface preparation standards — were developed to standardize surface preparation results and provide a template for the degrees of surface cleanliness to meet job specifications. This article provides brief descriptions of the WAB cleaning standards and the WJ surface preparation standards.

Wet Abrasive Blast Standards

These NACE/SSPC joint standards define the process for preparing a carbon steel surface to a specific degree of surface cleanliness using a WAB method of cleaning. They are intended for use by coating or lining specifiers, applicators, inspectors, or others whose responsibility it is to define a standard degree of surface cleanliness for carbon steel surfaces to be achieved by WAB cleaning.

WAB cleaning uses a mixture of water and abrasive that can produce various levels of surface cleanliness and surface profile (roughness). WAB cleaning may be specified when dust suppression is desired, and it may also be a means for reducing soluble salt contamination.

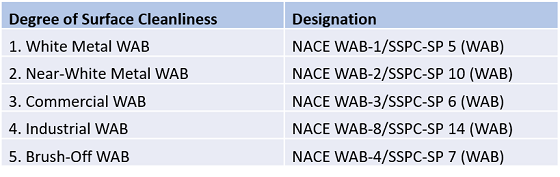

The five degrees of surface cleanliness achieved by a WAB cleaning method, each of which is addressed in a separate standard, are shown in Table 1.

1. White Metal WAB Cleaning: This NACE/SSPC joint standard defines the process for preparing a carbon steel surface to the white metal degree of surface cleanliness using a WAB cleaning method. White metal WAB cleaning is used when the objective is to remove all rust and other corrosion products, coating, mill scale, and other foreign matter from the surface. It does not permit any staining to remain on the surface.

2. Near-White Metal WAB Cleaning: This standard defines the process for preparing a carbon steel surface to the near-white metal degree of surface cleanliness using a WAB method. Near-white metal WAB cleaning is used when the objective is to remove all rust and other corrosion products, coating, and mill scale, but when the extra effort required to remove all stains of these materials is determined to be unwarranted. Near-white metal WAB cleaning allows staining on no more than 5 percent of each unit area of surface.

3. Commercial WAB Cleaning: This standard defines the process for preparing a carbon steel surface to the commercial degree of surface cleanliness using WAB cleaning. Commercial WAB cleaning is used when the objective is to remove all rust, coating, and mill scale, but when the extra effort required to remove all stains of these materials is determined to be unwarranted. Commercial WAB cleaning allows staining on no more than 33 percent of each unit area of surface.

4. Brush-Off WAB Cleaning: This standard defines the process for preparing a carbon steel surface to the brush-off degree of surface cleanliness using a WAB method of cleaning. The objective of a brush-off WAB cleaning is to allow as much of an existing adherent coating to remain as possible and to roughen the surface before coating application.

5. Industrial WAB Cleaning: This standard defines the process for preparing a carbon steel surface to the industrial degree of surface cleanliness using WAB cleaning. Industrial WAB cleaning allows tightly adherent paint, mill scale, and rust to remain on no more than 10 percent of each unit area of surface.

Waterjet Cleaning Standards

The WJ NACE/SSPC joint standards define the four degrees of surface cleanliness of coated or uncoated metallic substrates achieved by the use of waterjet cleaning before the application of a protective coating or lining. WJ is the use of pressurized surface preparation water for removing coatings and other materials, including hazardous materials from a substrate, to achieve a defined degree of surface cleanliness. WJ includes various methods, such as low-pressure water cleaning (LP WC), high-pressure water cleaning (HP WC), high-pressure waterjetting (HP WJ), and ultrahigh-pressure waterjetting (UHP WJ).

WJ does not provide the primary anchor pattern on the metallic substrate known as “surface profile.” The coatings industry uses WJ primarily for recoating or relining projects in which there is an adequate pre-existing surface profile. The degrees of surface cleanliness to be achieved by WJ methods are not intended to require that a surface profile be present or defined prior to coating application.

WJ reduces and may completely remove water-soluble surface contaminants, notably those contaminants found at the bottom of pits on the surface of corroded metallic substrates. WJ also helps remove oil, grease, rust and other corrosion products, and other foreign matter (e.g., shotcrete spatter) from the surface, and it is used when it is a more feasible method of surface preparation than, for example, abrasive blast cleaning, power or hand tool cleaning, or chemical stripping. WJ may be used when the application of high-performance coatings requires extensive surface preparation, surface decontamination, or both.

The waterjet standards are intended for use by coating or lining specifiers, applicators, inspectors, or others who have responsibility to define a standard degree of surface cleanliness to be achieved by WJ methods.

The four degrees of surface cleanliness achieved by WJ, which are addressed in separate standards, are shown in Table 2.

1. Clean to Bare Substrate: This NACE/SSPC joint standard defines the clean to bare substrate degree of surface cleanliness of coated or uncoated metallic substrates achieved by the use of WJ before the application of a protective coating or lining. WJ to achieve clean to bare substrate (WJ-1) surface cleanliness is used when the objective is to remove every trace of rust and other corrosion products, coating, and mill scale. Discoloration of the surface may be present.

2. Very Thorough Cleaning: This standard defines the very thorough cleaning degree of surface cleanliness of coated or uncoated metallic substrates achieved by the use of WJ before the application of a protective coating or lining. WJ to achieve very thorough cleaning (WJ-2) surface cleanliness is used when the objective is to remove almost all rust and other corrosion products, coating, and mill scale, but when the extra effort required to remove all of these materials is determined to be unwarranted. Discoloration of the surface may be present.

3. Thorough Cleaning: This standard defines the thorough cleaning degree of surface cleanliness of coated or uncoated metallic substrates achieved by the use of WJ before the application of a protective coating or lining. WJ to achieve thorough cleaning (WJ-3) surface cleanliness is used when the objective is to remove much of the rust and other corrosion products, coating, and mill scale, and leave tightly adherent thin films, but when the extra effort required to remove almost all of these materials is determined to be unwarranted. Discoloration of the surface may be present.

4. Light Cleaning: This standard defines the light cleaning degree of surface cleanliness of coated or uncoated metallic substrates achieved by the use of WJ before the application of a protective coating or lining. WJ to achieve light cleaning (WJ-4) surface cleanliness is used when the objective is to allow as much of the tightly adherent rust and other corrosion products, coating, and mill scale to remain as possible, but when the extra effort required to remove more of these materials is determined to be unwarranted. Discoloration of the surface may be present.

Conclusion

These joint NACE/SSPC WAB and WJ standards were developed to provide users with specific levels of cleanliness for each cleaning method to assure a well-prepared metallic surface and the best possible outcome for coatings applications. NACE offers its standards to the industrial and scientific communities as voluntary standards to be used by any person, company, or organization.

About the Author

Trudy Schreiner joined NACE International’s Technical Activities division in 2010 to assist standards development committees in the process of writing, revising, and publishing NACE’s corrosion-related industry standards, specifically in the coatings field. During her time with NACE, she has contributed magazine articles to both Materials Performance and CoatingsPro. For more information, contact: https://nace.org/standards

This article was originally published in CoatingsPro’s 2020 Steel Supplement.