Exterior coatings protect façade materials from damage caused by UV rays, rain, humidity, windborne particles, chemicals, mold, mildew and other environmental conditions. Asset owners want field-applied coatings to provide long-term protection and are turning to a new tool -- the Society for Protective Coatings (SSPC) Paint 47 Standard from the Association for Materials Protection and Performance (AMPP)– to help them determine how well the coatings they choose will stand the test of time. Here are a few things contractors should know about Paint 47.

When Coatings Fade

Even high-performance paints can quickly chalk, fade and degrade, especially those with deep colors and bright hues.

Chalking, caused by a physical breakdown of the coating's polymer, creates a white, powdery residue that compromises the coating's appearance but more importantly, its integrity on the surface. A chalked surface is the aftermath of erosion. Chalking also becomes a food source for mold and mildew growth and makes conditions ripe for dirt collection. It isn't always easy to see on white or off-white coatings, but it is obvious on darker colors as it changes their hue. It is a common problem with urethanes and acrylic latex paints, even high-performance grades, especially in high UV climates such as South Florida and Arizona, where their typical lifespan is about five years.

First Standard for Dark, Saturated Colors

There are several standards against which the coatings industry measures performance (see Table). However most, including the traditional standard for field-applied topcoats, SSPC Paint 36, were written around conventional 2k urethane technology and tested only in white. Even the Master Painter Institute (MPI) 311/315 Standard used by the federal government does not look beyond white, acrylic-based paint technology.

| AMMA 2605 | Aluminum | Factory bake | 10 | Any | Yes | None |

| MPI 311/315 | Any | Field-applied | - | - | No | Latex |

| SSPC Paint 36 | Steel | Field-applied | 1-4 | White or off-white | No | 2-component |

The industry's need to validate color retention in high chroma or saturated and bright colors prompted efforts by SSPC to develop a new standard to address the gap. The SSPC’s C.1.8 Fluoropolymer Topcoats Committee reached out to asset owners, architects, coating and raw materials suppliers, municipalities, and other stakeholders to ensure the new standard would meet their needs for color and gloss retention in "safety" and dark colors.

The resulting new “SSPC Paint 47 standard”, formally known as "SSPC-Paint 47-2020, Highly Weatherable Fluoropolymer Topcoat, Performance Based," issued at the end of 2020. Coatings meeting the requirements of this new standard will provide superior color and gloss retention properties when used as a topcoat over multiple substrates, including metals, plastics, wood, concrete, textiles and even some previously painted surfaces.

Accelerated Weathering Tests

Part of the SSPC committee's challenge was identifying a set of accelerated weathering test conditions to allow coating formulations to be qualified more quickly than possible with traditional outdoor service life tests, which can run for 10-50 years.

The committee followed the tenet that identifying an appropriate performance-based standard for low-color-fade fluoropolymer coatings should be restricted to specific fluoropolymer resin chemistries with proven performance. Moreover, the accelerated testing criteria for each chemistry type should be selected based on historical data for how commercially relevant coatings perform under natural as well as accelerated conditions.

Anonymized, round-robin weathering tests were conducted at two independent laboratories. Thirteen coatings (representing both fluorinated and non-fluorinated resin systems) from 10 different manufacturers were tested in four reference colors: white, NTPEP gray, mid-tone blue and safety red.

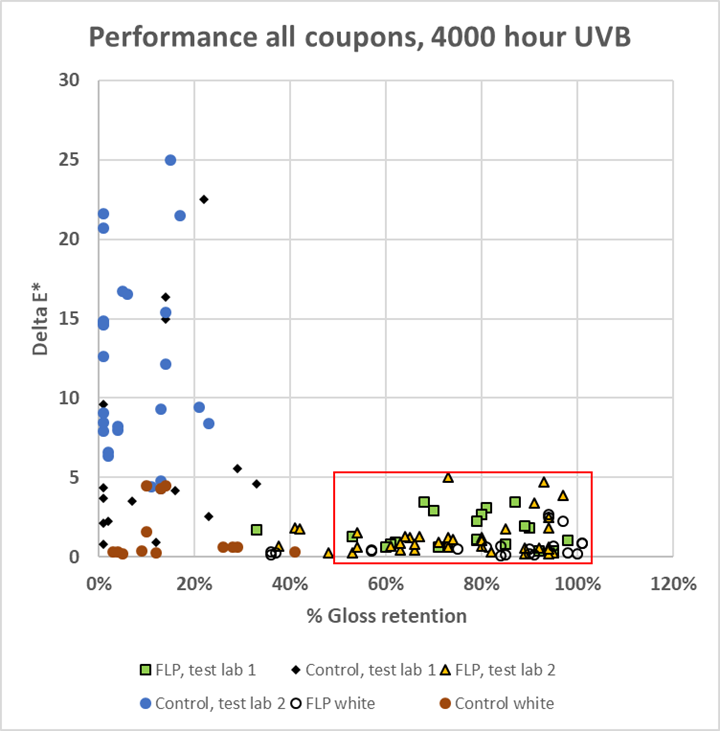

The most discriminating set of accelerated test conditions identified by the round-robin testing used a standard fluorescent test cabinet with aggressive UVB-313 bulbs, in a legacy cycle for 4000 hours (about 6 months). In that time, those accelerated test conditions accurately differentiated between high-weatherability fluoropolymer formulations and conventional SSPC Paint 36 (2-component polyurethane) and MPI 311 (latex) formulations, as shown in the Figure below. The accelerated test also uses virtually the same performance criteria specified in the well-recognized AAMA 2605 standard for factory-applied coatings undergoing a 10-year Florida exposure:

- Gloss retention >50% (ASTM D523)

- Color retention Delta E <5 units (ASTM D2244)

- Chalk rating > 8 (> 6 for whites) (ASTM D4214 Test Method A, in which 10 indicates no chalking)

PVDF-Based Coatings

Coating systems formulated with polyvinylidene fluoride (PVDF) resin deliver long-term performance – more than 20 years. This tough, engineered thermoplastic polymer promotes excellent weatherability, color retention and durability thanks to carbon-fluorine bonds that do not break down under exposure to the elements. One PVDF-based coating that meets Paint 47 specifications is the NeverFade® Façade Restoration Coating System from APV Engineered Coatings. NeverFade® Coatings contain Kynar Aquatec® PVDF latex, a water-based PVDF resin similar to the solvent-based Kynar 500® finishes trusted by architectural metal component OEMs for over 50 years.

Combined with the coating's complex inorganic pigments, the Kynar Aquatec® resin helps NeverFade® topcoats resist film erosion, chalking and fading, allowing APV to offer a 15-year product-and-labor guarantee that the coating will not fade by a Delta E of five or higher. Transferrable to future building owners, the guarantee is unique to the architectural coatings industry.

As with any coating, the long-term performance of formulas meeting Paint 47 specifications depends on compatibility among each coating in the multi-layer system. Moreover, the coating should be formulated to bond to a specific substrate to help ensure against coating adhesion failure.

Inadequate surface preparation and improper primer application are other ways through which a coating system can fail, so proper SSPC, NACE, ISO, and/or ASTM practices for surface prep and profiling should be employed. The primer must be engineered to bond well to the substrate while considering pre-existing conditions. Installation mock-ups can help to ensure issues are addressed before they become costly mistakes requiring re-work.

NeverFade® Coatings with Kynar Aquatec® PVDF resin can be formulated in custom colors, from whites and metallics to bold, bright hues like those covered under Paint 47, giving contractors a way to colorfully and sustainably lengthen the life of their customers' building facades with performance they can trust.