I was called to investigate a major paint failure: The paint was coming off the modules of a fast-tracked, rapid-delivery, and design-build facility in sheets, and the contractor needed answers right away. The stakeholders had a tight schedule with a huge penalty clause. Time was money on this project, and they needed answers fast!

Modular Design

A prefinished modular design had been chosen by the owner. All the walls and ceilings were gypsum board. The office area was finished with a latex paint system. For the remainder of the facility, the owners required a highly durable, aesthetically pleasing, easy-to-clean finish. The coatings selected for these areas were an epoxy/siloxane system.

When the modules arrived, there were a considerable number of areas where the coatings had cracked and debonded from the walls. This was primarily around devices that had been caulked. The caulking was a rigid, pick-proof material that did not allow for any movement. The coating was not well bonded to the gypsum substrate at these cracks. The edges could be easily picked at and further removed. It was assumed that this failure was caused by movement during shipping.

During the assembly of the office modules, the contractor noticed that the latex paint was peeling off the walls. In some areas, it was coming off in large sheets. There was one wall where most of the paint was removed right down to the gypsum substrate in a matter of minutes just by picking at a loose edge with one’s fingernails.

A painting contractor had been hired to repaint the modules once the assembly was complete, yet the painting contractor was at a loss as to what was causing these problems. It was thought that the fabrication shop had used the wrong primer or had not applied any primer. Neither the painting contractor nor the general contractor had seen this type of problem before.

Caulking Joint Failures

The project was already behind schedule because all of the prefinished walls and ceilings required repainting. To keep the project moving forward, the contractor needed to know what the problem was and who was responsible for the repairs. The repainting costs were going to be enormous. The stakeholders decided to bring in an independent, third-party inspector. Being an Master Painters Institute (MPI) inspector, I was brought in to diagnose the problem.

I noted that both the latex paint system and the epoxy/siloxane system were failing. There were a few small areas that had intercoat adhesion failures. These failures were typically around locations where the walls had been opened for mechanical work.

The failures at the caulking joints were all similar. These failures were determined to be caused by the movement from shipping. The modules had been assembled overseas, and it was not possible to discuss the problems with the fabrication shop. The concern was not that the coating had cracked at the caulking joints, but that the coating had completely disbanded from the wall at all of the failures.

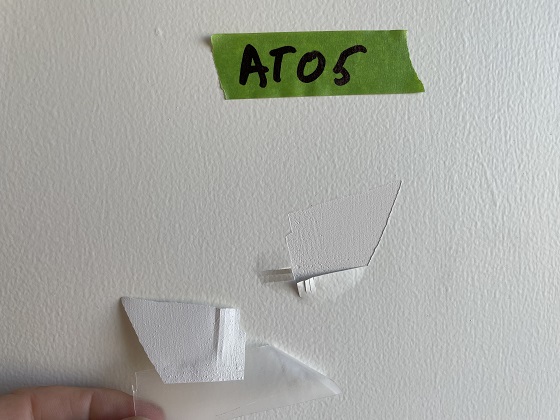

When an edge was picked at, the coating was easily removed. A small chip could easily turn into a large failure. The gypsum board behind had a rough finish wherever the coating was removed.

International Organization for Standardization (ISO) 2409 adhesion tests were conducted on the epoxy/siloxane system. The majority of the tests passed. However, a couple of tests showed minor coating failures; these failures all appeared to be in the adhesion to the gypsum substrate.

Office Area Level 5 Finish

The office area paint failures were considerably worse. The paint was all coming off the walls in sheets. The contractor thought that perhaps the problem was caused by a lack of primer on the walls.

I performed further ISO 2409 adhesion tests on these walls. All of the tests failed. The failures extended well beyond the test areas. There was little to no adhesion of the latex paint to the gypsum substrate walls.

All the walls with latex paint had the same problem: Once an edge was picked at, the paint was easily pulled off in large sheets. Close inspection revealed that the backs of all the failed paint samples had a film of joint compound on them.

When I investigated further, I discovered that the owner had wanted a high-end finish on all the gypsum wallboard surfaces. To obtain a uniform finish with the high-gloss epoxy/siloxane system, a level 5 drywall finish was specified. All of the walls had received a level 5 finish prior to paint application.

According to the Drywall Finishing Council (DWFC), a level 5 drywall finish is defined as follows: “All appropriately prepared gypsum board surfaces shall have one coat of drywall primer applied to yield a properly painted surface. Two separate coats of topcoat material shall be applied over the drywall primer to yield a properly painted surface. Paint shall be applied to the mil film thickness and application conditions specified by the paint manufacturer.”

The Gypsum Association states that a level 5 finish is, “Typically specified in appearance areas where smooth wall designs are decorated with non-flat paints (i.e., sheen/gloss) or other glossy decorative finishes, dark/deep tone paints are applied, or critical lighting conditions occur. The design professional shall clearly indicate the areas that meet these criteria on the finish schedule and/or plans, and specify the mock-up procedure and construction details within the project documents. This level of finish is the most effective method to provide a uniform surface and minimize the possibility of joint photographing and/or fasteners showing through the final decoration.”

In the case of these wall modules, the joint compound used for the level 5 finish was very soft and chalky. The compound was easily removed by lightly rubbing my hand across the surface. Even when a finger was rubbed over the same spot for a few seconds, with little effort, the compound was removed down to the gypsum board substrate.

Summary

As stated earlier, the backs of all the failed latex paint samples had a thin film of joint compound on them. Therefore, the plane of failure in this case was the joint compound used for the level 5 drywall finish on the walls.

There are a variety of joint compounds for use on the market. The soft joint compound was probably very easy to apply and sand, resulting in a smooth uniform finish on the walls, as had been requested by the owner, but it was a very poor substrate to which to apply additional paints and coatings. Just as a chain is only as strong as its weakest link, the best paint and coating systems are only as good as the substrate to which they are applied.

Key Takeaways

There are multiple reasons that a level 5 finish might fail. One failure that I had come across on a previous project was that the contractor had added too much water to the compound to make the application easier. This caused the compound’s tensile properties to break down, resulting in poor adhesion. The result was that the paint kept failing.

When specifying and implementing a level 5 finish, make sure that a premium quality product is used and that it is applied without alteration to ensure that the product performs as intended by the manufacturer.