It was a big year for the NFL and the Denver Broncos in 2016. The league began it by celebrating its 50th Super Bowl — a golden anniversary. And the team not only defeated the Carolina Panthers 24–10 in the big game, but they also said goodbye to one of the most recognized players in NFL history: Peyton Manning.

Considering the highlights reel, the Broncos needed to keep their next season going strong. To do so, as with the winning team, the famous mile-high stadium went through a transformation that following offseason — focusing on the top.

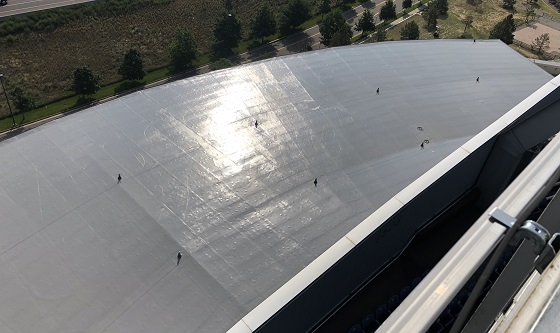

The outdoor stadium opened in 2001 in Denver, and four roofs that covered the pedestrian ramps hadn’t been replaced since then. The ethylene propylene diene terpolymer (EPDM)-type roofs, covered in a rubber coating, were breaking down and leaking in places. On top of that, the stadium had changed sponsors, and the previous Sports Authority logo up top needed to be removed.

Luckily, the right team for this job was located in central Denver, only about 15 minutes away. That was a 12-person crew from Preferred Painting, led by president and owner Chris Miller. The crew was not only fans of the “Orange Crush,” one of the Broncos’ team nicknames, but also seasoned — with some of the teammates having been with them for 20 years. This project had the makings of another great matchup!

Bring in the Thunder

Preferred Painting has worked with the Broncos in the past, so it made sense that they would be on the roster for this repair. The coatings company started by suggested six different coating manufacturers, and the client ended up choosing Castagra because of a recent positive experience with their coatings on a few floors.

“We had done some work there in some floors in the bar area and also in the bathrooms there. Those are heavy traffic — heavy beating type areas — and the coating had performed extremely well,” Miller said. So when Castagra came out with a successful case study from a roof done in sunny Phoenix, stadium management weighed the performance and financial benefits and decided on the Ecodur 201.

There were positives of the Castagra system for the coatings crew, too. Not only is there no scent, but the Ecodur 201 is also non-toxic, made from Castor oil and gypsum, and 100 percent solvent free, according to their website. That meant no need to wear respirators or to measure the thickness more than just once at the wet film thickness (WFT) stage. “There’s no change or loss or anything like that in terms of dry to wet. It’s easy to just measure the wet and know that you’re hitting it,” Miller explained.

The crew did wear fall protection up top. Those were Miller DuraFlex Python Safety Harnesses. And they lucked out in the weather department. Although Castagra products can be rained on 10 minutes after application and not cause any issues, the Preferred team didn’t have to worry even about their own safety. “We got lucky: No lightning storms or anything we encountered during it,” Miller said.

Simple and Straightforward

The stadium’s ramp roofs covered about 15,000 square feet (1,393.5 m2) each and totaled 60,000 square feet (5,574.2 m2). Four roofs in varying stages of production called for about 3 to 3.5 days per roof.

Although there were no official games going on during the off season, the stadium did hold other events occasionally. And with preseason games on the horizon, there was no time to stop work and call an audible. “Luckily, we can move stuff into corners out of the way when we have to, but, in general, getting it done before the season was always the goal,” Miller said.

Although there were no official games going on during the off season, the stadium did hold other events occasionally. And with preseason games on the horizon, there was no time to stop work and call an audible. “Luckily, we can move stuff into corners out of the way when we have to, but, in general, getting it done before the season was always the goal,” Miller said.

To help hit that mark, the crew split up into two teams, similar to offensive and defensive lines. One team prepped a roof while the other team coated it, continuing to move those chains.

Preferred Painting started each roof with a power washing. Wielding a Mi-T-M ChoreMaster Series at 3,200 psi (22.1 MPa), the first team sprayed a solution called Simple Green onto the substrate. According to Miller, it’s diluted and environmentally friendly. “It really is just to help if there’s any kind of film or anything sticking to the roof,” he said. Once the crew had repaired and filled any damaged cracks or gaps and let the roof dry, it was time to move onto a full topcoat.

The coating team was made of six — two guys mixing up kits, two guys squeegeeing and backrolling, one on a lift (supplied by the Broncos), and one on the concourse. They used Rubimix Electric Mixer with chuck and M120-R paddle and Rubimix 9N Mortar Mixer for the Ecodur. “You have to take it and weigh out the specific components, so we mixed them in the smaller hand-sized buckets,” Miller explained. The coating was applied to an average of 30 mils (762.0 microns) using 36-inch (91.4 cm) width Flo-Pac Curved End Black Rubber Squeegees with Metal Frames from Carlisle.

As Miller explained, the application of the Ecodur was straightforward — and that was a benefit, especially since these roofs aren’t protecting rooms or offices below. “The big thing with the project is just the simplicity of it to clean and apply,” he said. “As a coatings company, a lot of our time and a lot of our cost and labor, are put into preparations so to have a very simplistic preparation. And then have the performance that we’ve seen with it is what makes it an attractive option.”

Saving time on Preferred’s end saves the client money, too. “The real piece with [Ecodur 201] is it’s a product that has great adhesion to the majority of substrates,” Miller explained. “So rather than having to go in and do a bunch of repairs to the roof, we were able to build a membrane with Castagra over it, and that’s really where you eliminate a lot of the costs — in prep work and repairs.”

Dream Team

Preferred Painting walked the project with the client before leaving the field. And they walk it once a year to “continue to monitor the performance of the coating,” Miller said. Talk about an MVP performance! “It’s been a lot of fun,” he said. “We’ve been there when Peyton Manning came and have been there through some of the ups and downs of the recent seasons, but overall they have a fantastic team that works at the stadium, and it’s a fun environment to work at.”