Being struck by falling objects kills hundreds of individuals each year and injures tens of thousands more. According to the most recent statistics, there were 247 deaths in 2015 attributed to impacts from dropped tools and other objects. Liberty Mutual reported that “struck by” incidents were up 8.6 percent that year, and the organization spent $5.3 billion on workers’ comp claims due to struck by incidents from 2013 to 2014.

An increasing number of people are finding themselves ascending to heights to accomplish their projects. Often, they are directly over or adjacent to their colleagues, bystanders, and other individuals at lower levels. Protective equipment and preventative measures, such as hard hats and toe boards, has long been available with standards written to minimize the effects of struck-by incidents, but often this only goes into effect after an object has fallen.

Now, with the use of cell phones and tablets, we need to use active controls to prevent falling tools and objects by tying them off or containing them with tethering systems. This is a rapidly growing proactive safety practice.

Despite such a high risk to workers’ safety, until now there have been no standards in place to guide manufacturers and safety engineers on the proper safety criteria of tethering products. Over the past two years, the International Safety Equipment Association (ISEA) developed a standard for equipment tethering solutions that can prevent dropped tools and other objects.

By establishing manufacturing guidelines for tethering systems, American National Standards Institute (ANSI)/ISEA 121-2018 is a significant first step in reducing dropped tool incidents. The new ANSI/ISEA standard establishes minimum design, performance, and labeling requirements that can mitigate this hazard. Safety engineers and end users can feel confident that any ANSI/ISEA-compatible tool tethering system they choose has met these guidelines.

Scope of “Dropped Object” Standard

The release of the new ANSI/ISEA “Dropped Object” standard was officially released on July 3, 2018. Working with ISEA, this standard was developed in conjunction with companies that have had a long history in the manufacturing of tethering systems. With their combined knowledge based on decades of developing and testing safe tethering systems, these companies put their experience to work resulting in the criteria that became the foundation for ANSI/ISEA 121.

Four main categories of products are referenced in the new standard: anchor points, attachment points, tool tethers, and anti-drop storage. The standard establishes design, testing, and performance criteria for active systems used to prevent dropped objects in the workplace. Recognizing the benefit of these active prevention practices, it was the mission of the ANSI/ISEA and this group of manufacturers to create guidance for this equipment.

The standard establishes minimum design, performance, testing, and labeling requirements for solutions that reduce dropped object incidents in industrial and occupational settings. Dropped objects include hand tools, instrumentation, small parts, and structural components that are used at heights. These objects have the potential of becoming dropped objects possibly resulting in struck-by injury or fatality or damage to equipment. The standard focuses on preventative solutions actively used by workers to mitigate these hazards.

The standard does not address passive preventative solutions such as netting, barricades, and toe boards, nor does it address protective solutions for dropped objects that minimize damage from falling objects, including head, foot, or eye protection. The standard also does not address hoisting or lifting requirements for material handling. These solutions are described in other standards when applicable.

The standard will require manufacturers to provide instructions on how to use tethers, attachments, anchors, and containers. However, not all work environments can be addressed specifically, and, therefore, it will be the responsibility of the end user and safety professional to evaluate the environment and make sure the worker is not put into danger by preventing a dropped object incident. For example, attaching too much weight to a worker could cause him or her to fall, so it will be up to his or her company to determine the weight limits and communicate that to the crew.

Why Is This Important?

ANSI/ISEA 121-compliant tethering systems include many different components (i.e., tool attachments, lanyards, carabiners, and anchor points) that should work safely together, even when purchased from different ANSI/ISEA 121-compliant manufacturers. It is also important to note that currently ANSI/ISEA 121 does not tell you when and how to tether your tools, although it does provide some information and recommendations in the appendix.

The work of supplying end user groups and safety organizations with guidance is still continuing. In the very near future, ISEA, with the support of the manufacturers’ group and input from end users, is developing additional online resources about how to apply the standard to its work at heights program and policies. These resources may include FAQs and webinars.

The tool tether’s length and the weight that it can carry safely, as required by the standard, are the critical limiting elements in safe tethering. The ratings and labeling requirements of the ANSI/ISEA standard will allow for a user to safely couple components. (See Weight and Length Compatibility Example.)

The ANSI/ISEA requirement is that the rated tool attachment is greater than or equal to the weight of the tool, and that the tether weight limit and the anchor weight limit must be equal to or greater than the weight allowance of the tool attachment.

Furthermore, the tool attachments and anchor points have a maximum lanyard length based on the length of their lanyard test. Also, the tethers have a maximum length. Therefore, in addition to the tool weights, the end user must ensure that the tool attachment and anchor points have a maximum tether length that is less than or equal to the tether that they are being used with.

This may sound complicated, but it is not. That figure shows a 4-foot (1.2 m) tether (weight limit 10 lbs., 4.5 kg), a tool (weight 5 lbs., 2.3 kg), and an anchor point (weight limit 15 lbs., 6.8 kg). These are three different weights, but they are compatible for safe tethering.

Here’s how it breaks down:

1. The 10-lb. tether is the critical element iin this scenario; this is the maximum weight limit of this system.

2. The tool that is attached to the tether weighs 5 lbs., which is less than the tether’s 10-lb. weight rating. Thus, the tool (and tool attachment) is compatible with the tether.

3. The 10-lb. tether is attached to the tool belt anchor point, which has a weight rating of 15 lbs. (more than the tether’s weight rating of 10 lbs.), so the anchor point is compatible with the tether’s weight rating. Again, even though the anchor point is rated at 15 lbs., the maximum weight limit of the system is 10 lbs.

4. Since the tool’s 5-lb. weight is within the tether’s tool weight limit and the tether’s weight limit is less than the weight limit of the work belt’s anchor point, this is a safe tethering solution.

One additional situation that users might encounter is when they wish to use a tether with a higher weight rating than the anchor point. This can be allowed as long as the user understands that the max weight rating of the entire system is the lowest weight rating. For example, if the user had a 15-lb. tool tether and a 10-lb. anchor point, this would work for our example above — as long as the user understood that the max tool weight they could use with the system was 10 lbs.

Since users may find themselves using various components with different ratings, it is important that they understand the above to maintain a safe working situation.

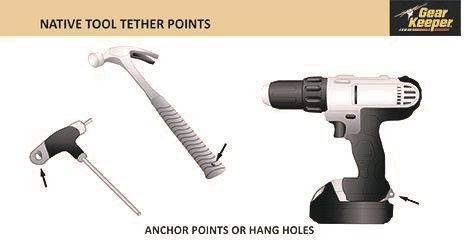

When tethering tools and other small objects that have built-in attachment points or hang holes, it is also recommended that users contact the tool manufacturer to determine if the native attachment point is compliant with ANSI/ISEA 121 tool attachment testing requirements (see Native Tool Tether Points).

About the Author:

John Salentine is the co-founder and vice president of Hammerhead Industries. Gear Keeper tool tethering systems are products of Hammerhead Industries, Inc., the world’s leading manufacturer of unique personal safety tethering equipment. This equipment includes retractable tethers and lanyards for tools, gear, and instruments. For more information, contact: Hammerhead Industries, https://gearkeeper.com/