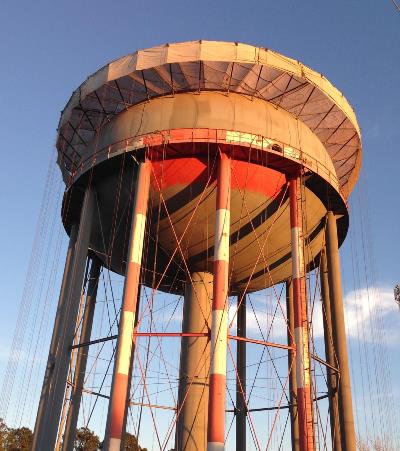

Operated by U.S. water and wastewater utility American Water, a massive 1,000,000-gallon (3,785,412 L) elevated water tank welcomes visitors to Fort Polk, Louisiana. The U.S. Army installation, located near the Texas border, has served as an Army training base since 1941, and troops continue to march through the streets to this day.

So when a 10-man crew from coatings contractor Blastco, a TF Warren company, arrived at the site in October to recoat both the exterior and interior surfaces of the carbon steel tank, they immediately found a number of unique challenges.

“They would do their morning drills, or marches, basically up that main street,” recalled Blastco General Manager (GM) Steve Wissing. “We were limited on where we could access the site. On top of that, it’s very exposed, so you have a lot of people nearby. There was definitely added risk there.”

That heightened risk didn’t stop with just the presence of troops, either.

“Because the tank was positive for lead, all lead abatement procedures had to be followed,” Wissing said. “The coatings were in poor condition, with moderate metal loss and corrosion. With a lead tank and that kind of condition, you have to be on your game a little more.”

Containment Strategy

With the presence of lead and troops routinely marching through the main thoroughfare below, safety was even more important than usual for the Blastco team. Standard personal protective equipment (PPE) was a must, including steel-toed shoes, eye protection, hard hats, and ear protection. They also needed to wear harnesses and lanyards from Guardian Fall Protection.

“There has to be 100-percent tie-off when working above 6 feet [1.8 m], and that was nearly all the time on that tank,” Wissing said.

In addition to regular PPE, the Blastco team had to follow extra protocols based on the presence of lead-based paint, such as the regular collection of bloodwork from workers to monitor the presence of lead and even bringing a decontamination trailer to the site. “This was so that when they came out of the containment area, there was an immediate washdown area where they could blow themselves down,” Wissing explained.

In addition to regular PPE, the Blastco team had to follow extra protocols based on the presence of lead-based paint, such as the regular collection of bloodwork from workers to monitor the presence of lead and even bringing a decontamination trailer to the site. “This was so that when they came out of the containment area, there was an immediate washdown area where they could blow themselves down,” Wissing explained.

When directly working on the tank’s exterior, tarps were constructed for full containment. That process took at least two weeks, the GM recalled, adding that all lead abatement procedures were followed to meet the Society for Protective Coatings (SSPC) QP2 standard for field removal of hazardous coatings.

The American Water safety manager visited the site on a daily basis, too, so the Blastco crew knew they had to get everything just right.

Marching Orders

The first month of the job, which lasted close to eight months in total, consisted of installing various weld repairs, which had been bid into the project package. Structural upgrades included new hatches, vents, ladders, and overflow piping, while electrical upgrades consisted of a new conduit and fittings. Meanwhile, the crew also constructed a new concrete masonry unit (CMU) building to house the existing altitude valve and associated piping.

With upgrades complete and safety and containment strategies deployed, the crew began working on the tank’s exterior with a three-coat system in mind. Using an ARS Recycling machine with recyclable steel grit, the crew blasted the exterior to achieve a NACE No. 3/SSPC Surface Preparation (SP) 6: Commercial Blast Cleaning. As each section of the tank was blasted, it was primed the same day with the Corothane I Galvapac Zinc Primer 1K from Sherwin-Williams in a gray color at 2.5 to 3.5 mils (63.5‒88.9 microns) dry film thickness (DFT).

After blasting and priming the tank’s entire exterior and allowing each section to cure, the crew applied Macropoxy 646 PW intermediate coat from Sherwin-Williams in a white color at 3 to 6 mils (76.2‒152.4 microns) DFT over the same areas. Both the zinc primer and intermediate epoxy coat were spray applied using Graco pumps and equipment, and Wissing said relatively calm winds during a mild Southern winter alleviated most overspray concerns.

“The zinc and epoxy provide the corrosion protection, while the polyurethane provides the UV [ultraviolet] protection,” Wissing noted.

Accordingly, the finish coat of Sherwin-Williams’ Hi-Solids Polyurethane was applied in alternating orange and white colors, per U.S. Federal Aviation Administration (FAA) rules, using 9-inch (22.9 cm) rollers to reach 2‒3 mils (50.8‒76.2 microns) thickness. “This tank was in the flight path, and those tanks have to be painted a certain way,” Wissing said. In all, between building and removing containment devices and all coating processes, it took close to three months to finish the exterior assignment.

The good news was that after finishing the exterior, the hard part was over! The interior had less square footage, and lead containment was no longer an issue. Utilizing a dehumidification (DH) system to maintain conditions, the interior was blasted to a standard of NACE No. 2/SSPC-SP-10: Near-White Metal Blast Cleaning, and the zinc primer was again immediately applied to the same thickness. But as opposed to one epoxy coat and one polyurethane, as on the tank’s exterior, the interior was finished with two coats of the epoxy since the UV protection of a polyurethane was not needed inside. The epoxy coats were spray applied in two separate passes of 4‒6 mils (101.6‒152.4 microns) DFT each. In all, the interior work lasted barely over a month.

Job Secure

After spending only a few more weeks on closeout operations, the 10-man crew finished the entire Fort Polk assignment by June!

“This was a large tank,” Wissing said. “It was a big job. But the client was more than happy, and our team did a really good job.”

Perhaps best of all, the success on this tank has already led to further developmental plans at the base for both the client and contractor.

“Because everyone was so pleased with the crew, they awarded another tank to us,” Wissing said. “So it appears we have a new repeat customer, which is exactly what we are trying to accomplish.”

Roger that!

.jpg)